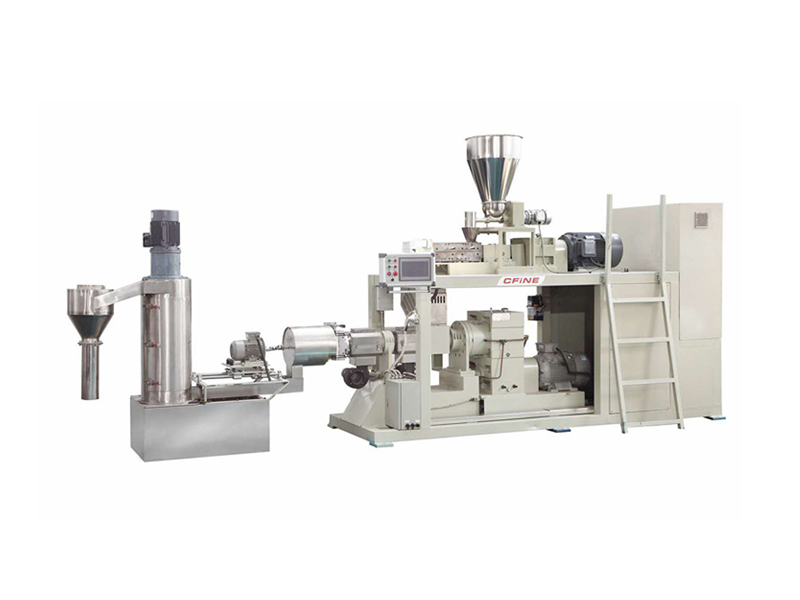

Application of Continuous Mixer in Rubber Processing

Continuous mixing machines have the characteristics of continuous production. Compared with traditional intermittent mixing machines, they can reduce the time and operation of loading and unloading materials, save human resources, and achieve automation of the production process. The effective internal mixing process is adopted, which can continuously mix rubber raw materials and various additives, and lubricate and heat the mixed rubber material to improve its plasticity and processability. In this way, production efficiency can be greatly improved, production time can be reduced, and labor intensity of workers can be reduced.

In rubber processing, product quality can be improved. Internal mixing is an important part of rubber processing, which has a direct impact on the performance and quality of rubber products. By adopting a scientifically reasonable mixing process, various additives and additives in rubber materials can be evenly dispersed in the rubber matrix, avoiding waste and accumulation of additives and additives, and improving the stability and consistency of rubber products. In addition, rubber can also be subjected to high-temperature mixing, allowing it to fully react with additives and additives at high temperatures, promoting the diffusion and reaction rate of reactants, enhancing the heat resistance, wear resistance, and aging resistance of rubber.

Continuous mixing machines can also reduce production costs. The traditional intermittent mixer production has problems such as long cycles, high energy consumption, and high manual labor intensity. Due to continuous operation, the internal mixer can greatly shorten the production cycle, improve production efficiency, and reduce energy consumption. In addition, due to the characteristics of automated production, it not only reduces manual operations, but also avoids the risk of operators coming into contact with rubber materials and harmful gases during the rubber processing, improving production safety and stability. In addition, an efficient and energy-saving heating system has been adopted, reducing heating time and energy consumption, and lowering production costs.